React 120

CTM Magnetics RHF load reactors are designed for optimal performance with high frequency (0 – 500Hz+) applications. Engineered for high frequency load side applications, RHF reactors are effective in mitigating harmonic distortion and protecting equipment.

Applications

CTM vs. The Competition

CTM

- No common mode noise

- Highly efficient patented inductor technology

- High frequency capable to 500 Hz+

- No derate required

- Fully liquid cooled solutions

- Integrated cooling system

- Military grade shock & vibrations

The Competition

- Produces common mode noise

- Inefficient silicon steel inductors

- Air cooled only

- Limited high frequency capabilities

- Significant derates required for frequencies above 70 Hz

- Cooling system not included

- Low shock & vibration capabilities

Product Highlights

High Frequency

- 0 – 500 Hz+ capable

- No high frequency derate

- High efficiency at high frequencies

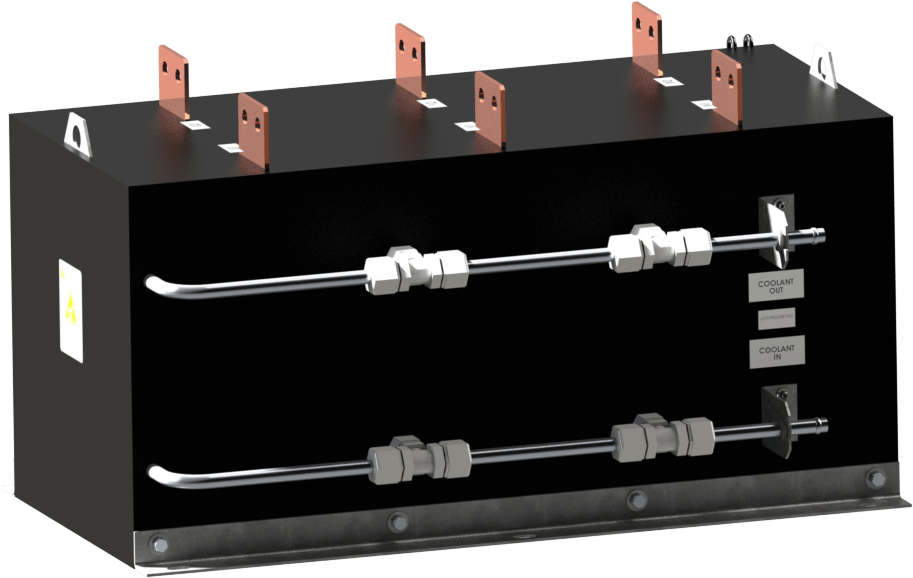

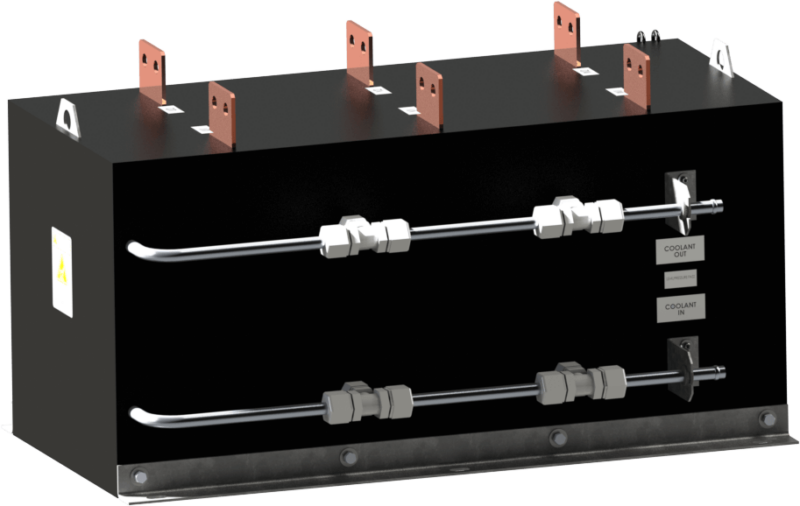

Liquid Cooling

- Unparalleled power density

- Best in class thermal efficiency

- Minimal heat to surrounding environment

- More flexibility with packaging

Military Shock & Vibration

- Explosive and extreme shock & vibration tested

- Unparalleled ruggedness & longevity

Efficient Design

- Highly efficient capacitors

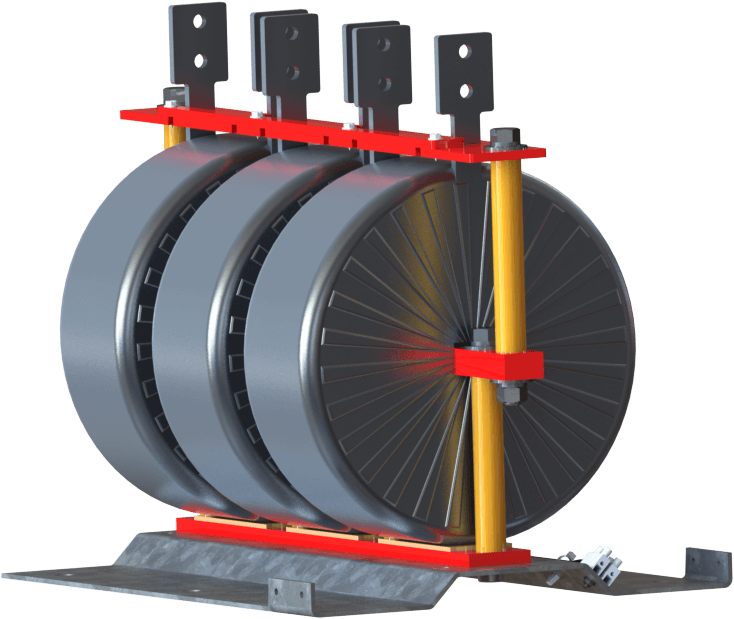

- Patented inductor technology

- Smallest size

- Best in class performance

The Optimal Reactor Solution for High Frequency Motor Protection

High Frequency Motor Protection:

Harmful square waves, voltage spikes, and harmonic distortion are filtered from the inverter output, reducing motor heating, wear, and winding stress, providing critical motor protection. With the rise of high frequency/ high speed permanent magnet motors the need for higher frequency reactors has increased. CTM RHF reactors are designed to meet this rising need without requiring costly derates that negatively effect system size, efficiency, and cost.

Stop Rewinding Motors:

CTM RHF reactors reduce harmful voltage spikes and insulation stress. RHF reactors lessen harmonic current distortion, thereby minimizing unnecessary motor heating. By reducing winding stress and motor heat (two primary causes of motor winding failure), motor winding breakdown and failure is greatly reduced, minimizing the need to constantly rewind motors.

Extended System Life and Reliability:

CTM RHF reactors reduce voltage stress and excess heat not just for the motor, but for all other load side components, greatly extending the life and reliability of the entire system.

Inductor Efficiency:

CTM Magnetics patented inductor technology enables highly efficient reactor designs for high frequency applications.

Power Density:

Innovative packaging and cooling systems, combined with highly efficient inductors enable unparalleled power density.

Liquid Cooling:

CTM Magnetics patented liquid cooled technology enables higher thermal efficiency, power density, and performance. With liquid cooling, 97% of the reactor heat is captured by the coolant with only 3% released to ambient. This reduces the need for additional cooling and allows for more flexibility in locating reactors near temperature sensitive equipment.

Military Grade Shock & Vibration:

CTM liquid cooled RHF reactors have been tested and passed rigorous explosive and extreme shock & vibe military testing. RHF liquid cooled reactors are the optimal choice for mobile, marine, and military applications.

React 120 Product Specs

Harmonic Distortion

<5% THVD @ 2 kHz

Voltage Range

480 V ±10%

Fundamental Frequency

6 - 70 Hz (Higher with derate)

Switching Frequency

2 - 20 kHz (above 8kHz, contact CTM)

Current Range

100 A - 1080 A (Air Cooled) | 100 A - 1,440 A (Liquid Cooled)

Enclosure Options

Modular Panel | NEMA 3R Cabinet

Motor Cable Length

Up to 15,000 feet

Agency Recognitions

cЯUus 1446 | UL 508A

Overload Capability

150% rated current for 1 minute (Air Cooled)

200% rated current for 1 minute (Liquid Cooled)

Ambient Temperature Range

Maximum: 50 °C (122 °F) (Air Cooled) | 65 °C (149 °F) (Liquid Cooled)

Minimum: -40 °C (-40 °F) (Air & Liquid Cooled)

Preventative measures should be taken to ensure the coolant does not freeze in the system.

Get a Custom Design in just 2 Business Days

We are here to work with you every step of the way.

Other Reactors

Product Categories

-

EV Inverter Testing

-

Harmonic Filters

GridHawk® harmonic filters are engineered to eliminate harmonic distortion and enhance power quality.

-

Sine Wave Filters

CTM output Sine Wave Filters eliminate switching harmonics produced by VFDs, protecting motors.

-

Transformers

CTM 3-phase transformers are the ideal choice when extreme shock & vibe capability or liquid cooling is required.