Power Quality Solutions: Land & Sea

Transporting people and goods from point to point consumes energy, most often in the form of oil and its byproducts—gasoline, diesel fuel, kerosene, natural gas and others. However, in an increasing number of cases, electricity is used directly to drive transportation. While electric power is a generally a cleaner and more efficient power solution, its efficiency and cleanliness is dependent on its energy source as well as the efficiency of the power conversion process. Similarly, its reliability is dependent on the source’s reliability. Take a look below at the type of power utilized by transportation vehicles around the world, and why power quality solutions are needed for the future of the industry.

Rail Transportation

Rail transportation can be divided into two basic types based on their application. Passenger trains, as the name implies, move people from point-to-point. They are characterized by high speeds, frequent stops, and (generally) shorter routes. Freight trains transport goods and cargo, and are characterized by high efficiency, large capacity, infrequent stops, and long routes.

Locomotives (vehicle that provides motive power) can generally be divided by their power source. Steam locomotives provide power through a steam engine, which creates mechanical power to directly drive the locomotive. Steam engines have been phased out in most applications.

The two other main power sources for locomotives rely on some form of electricity. Electric locomotives draw power from an overhead wire or third rail. Some will supplement or replace this power with a local battery. High voltage, low current electricity is converted into low voltage, high current power, which is used to power motors in the wheels. Electricity is produced off-site at a generating station. Electric locomotives are often powered by three-phase, AC induction motors. These induction motors require variable speed drives to provide the proper voltage, current, and frequency for transient and steady-state operation.

Diesel locomotives are generally powered by a two-stroke, turbocharged diesel engine that can generate more than 3,000 horsepower. However, that power isn't used to drive the wheels; it's used to generate electricity. The generator on a typical locomotive can generate more than 4,000 amps of current, which is delivered to electrical motors connected to drive wheels that pull the train. A bank of batteries provides power necessary to start the diesel engine, and to temporarily store regenerative power.

Additionally, diesel locomotives are equipped with a main power generator that produces electricity to power lights, kitchen appliances, air conditioners and other devices. A second diesel engine drives that generator to produce more than 500 kW of three-phase, 480 VAC power.

Alternative sources of motive power exist. Magnetic levitation (MagLev) trains are gaining popularity due to their high speed and high efficiency capabilities.

Another way trains use electricity is through dynamic braking. As the train decelerates, the locomotive's drive wheels transfer the kinetic energy of the train back into the drive motors, essentially turning them into huge electrical generators capable of producing hundreds of Amps of current flow. In non-regenerative systems, that electrical energy is dissipated through banks of high power resistors that convert electrical current into heat energy. In regenerative systems, instead of dissipating electric energy as heat in resistors, braking electricity is used to charge onboard batteries, which can be used as starting or peaking power, or for other onboard electric loads.

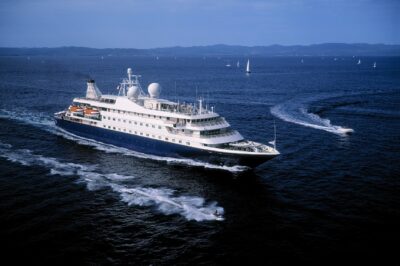

Transportation by Ocean

While passenger sea travel has waned since the proliferation of aviation, oceanic transportation remains the cheapest was to ship goods across large distances. Cargo and passenger ships today are typically powered by diesel engines, steam engines, gas turbine engines or electric motors. In each case, large ships use generators or alternators to generate electricity for a wide variety of electrical devices—passenger cabins, kitchen facilities; cranes, gantries and elevators; lighting, command and control computers, communications, and more. The electrical power plant in a typical cruise liner might use a series of alternators that produce 11 kV on the main bus rated at 10 to 20 MW with appropriate step-down transformers at sub-stations to serve various devices on board.

While passenger sea travel has waned since the proliferation of aviation, oceanic transportation remains the cheapest was to ship goods across large distances. Cargo and passenger ships today are typically powered by diesel engines, steam engines, gas turbine engines or electric motors. In each case, large ships use generators or alternators to generate electricity for a wide variety of electrical devices—passenger cabins, kitchen facilities; cranes, gantries and elevators; lighting, command and control computers, communications, and more. The electrical power plant in a typical cruise liner might use a series of alternators that produce 11 kV on the main bus rated at 10 to 20 MW with appropriate step-down transformers at sub-stations to serve various devices on board.

In recent years ship builders have added solar power to their designs to supplement the electricity generated by petroleum products. A typical installation might generate enough power to operate ten residential homes, and can provide around 10 percent of the ship's overall electrical requirement. Increasingly, solar panel structures are connected directly to the ships main power grid rather than simply serving secondary functions such as powering running lights.

Power Quality Is Crucial for Today's Transportation Industry

Whether transportation is by land, sea, or air, power quality has become more important than ever, both now and in the future. Increased electrification of transport vehicles is pushing the demand for power quality solutions in the transportation industry. CTM Magnetics has led the field, incorporating the latest proven technology into its power quality products.

" alt="">

" alt="">