Sine 60™ (60 Hz)

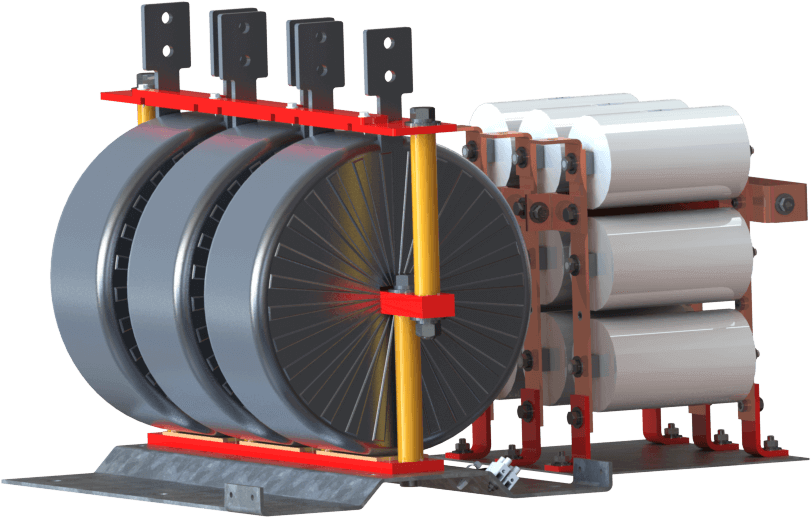

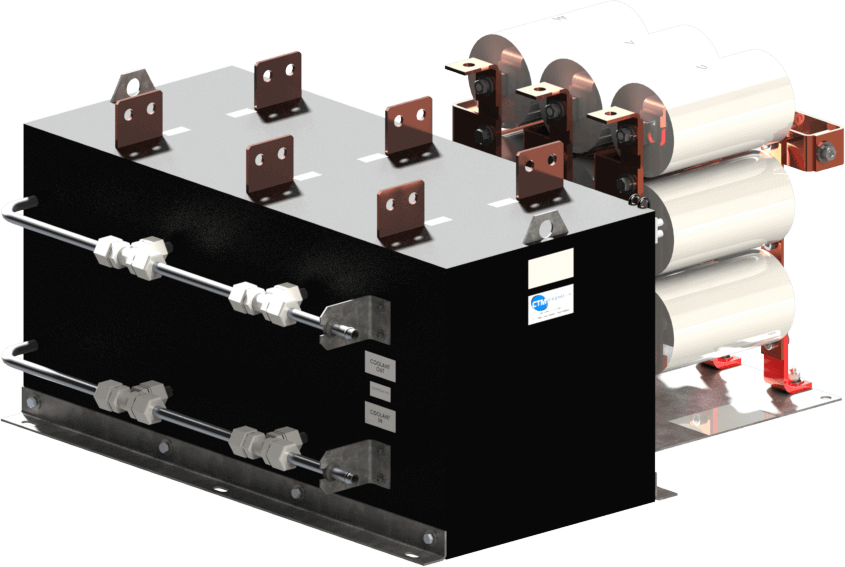

CTM Magnetics Sine 60™ sine wave filters are designed for optimal performance with line frequency, 60 Hz, motors. Attenuated for PWM switching frequencies as low as 2 kHz (and up to 20 kHz), Sine 60™ (60 Hz) sine wave filters will meet your most demanding motor filtering needs for all 60 Hz applications. CTM Sine 60™ sine wave filters are available in multiple packaging configurations and come with both air and liquid cooled options.

Applications

CTM vs The Competition

CTM

- Highly efficient patented inductor technology

- Highly reliable film capacitors

- Integrated cooling system

- Fully liquid-cooled options

- Military grade shock & vibration

- No common mode noise

The Competition

- Inefficient silicon steel inductors

- Cooling system not included

- Air cooled only

- Low shock & vibration rating

- Produces common mode noise

Product Highlights

Efficient Design

- No derate

- Smallest size & optimized cost

Reliable Performance

- Thermally protected capacitors & inductors

- Highly efficient patented inductors & capacitors

- No common mode noise

Plug & Play

- Simple 3-in/3-out connection

- No additional cooling required

Environmentally Rugged

- Dust, wind, rain, weather proof (NEMA 3R)

- -50 °c - +50 °c

The Optimal Solution for Motor Protection

Motor Protection:

Harmful square waves, voltage spikes, and harmonic distortion are all filtered from the inverter output, reducing motor heating, wear, and winding stress, providing critical motor protection.

Maximum Motor Lead Length:

Damaging voltage waves occur when motor lead lengths reach a characteristic length. These reflected voltage waves can cause damage to cable insulation and motors. By filtering the drive produced PWM waveform to a near perfect sine wave, CTM sine wave filters minimize harmful voltage, allowing for longer motor lead lengths (up to 15,000 feet in certain applications).

Stop Rewinding Motors:

Installing a CTM sine wave filter eliminates harmful voltage spikes, reducing insulation stress. CTM sine wave filters lessen harmonic current distortion, thereby minimizing unnecessary motor heating. By reducing winding stress and motor heat (two primary causes of motor winding failure), motor winding breakdown and failure is greatly reduced, minimizing the need to constantly rewind motors.

Extended System Life and Reliability:

CTM sine wave filters greatly reduce voltage stress and excess heat not just for the motor, but for all other load side components, greatly extending the life and reliability of the entire system.

Sine 60™ Product Specs

Harmonic Distortion

<5% THVD @ 2 kHz

Voltage Range

480 V ±10%

Fundamental Frequency

6 - 70 Hz (Higher with derate)

Switching Frequency

2 - 20 kHz (above 8kHz, contact CTM)

Current Range

50 A - 1,500 A (Air Cooled) | 50 A - 2,000 A (Liquid Cooled)

Enclosure Options

Open Chassis | NEMA 3R Cabinet

Motor Cable Length

Up to 15,000 feet

Agency Recognitions

cЯUus 1446 | UL 508A

Overload Capability

150% rated current for 1 minute (Air Cooled)

200% rated current for 1 minute (Liquid Cooled)

Ambient Temperature Range

Maximum: 50 °C (122 °F) (Air Cooled) | 65 °C (149 °F) (Liquid Cooled)

Minimum: -40 °C (-40 °F) (Air & Liquid Cooled)

Preventative measures should be taken to ensure the coolant does not freeze in the system.

Get a Custom Design in just 2 Business Days

We are here to work with you every step of the way.

Other Sine Wave Filters

Product Categories

-

Reactors

CTM input and output reactors mitigate harmonic distortion on the input and output of VFDs.

-

Harmonic Filters

GridHawk® harmonic filters are engineered to eliminate harmonic distortion and enhance power quality.

-

Transformers

CTM 3-phase transformers are the ideal choice when extreme shock & vibe capability or liquid cooling is required.

-

Other Products

We offer a range of power quality solutions designed to enhance efficiency and ensure robust, reliable performance. Our products help minimize harmonic distortion, improve energy efficiency, and promote smooth operations across demanding industrial and commercial applications. Whether optimizing motor drives, stabilizing power systems, or reducing electrical noise, our engineered solutions deliver the performance and durability needed for modern power infrastructure.