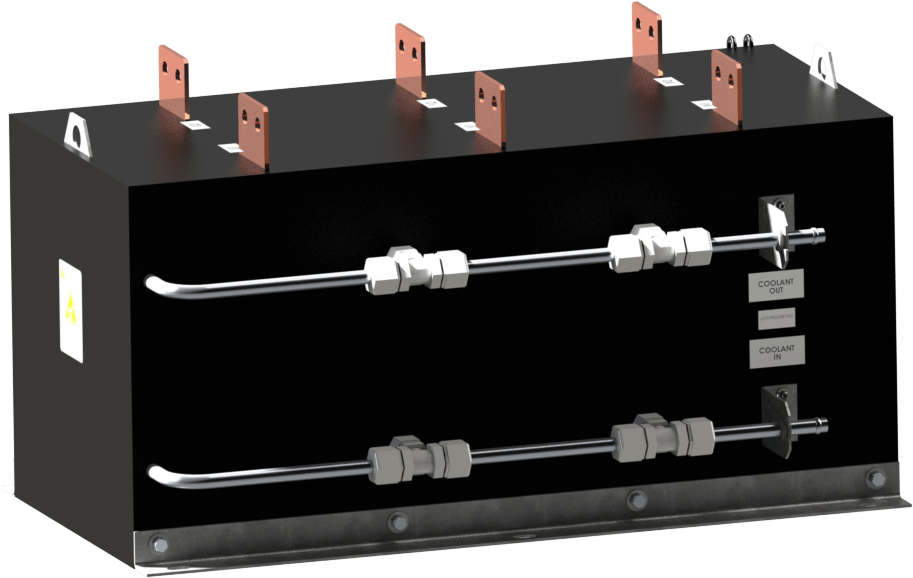

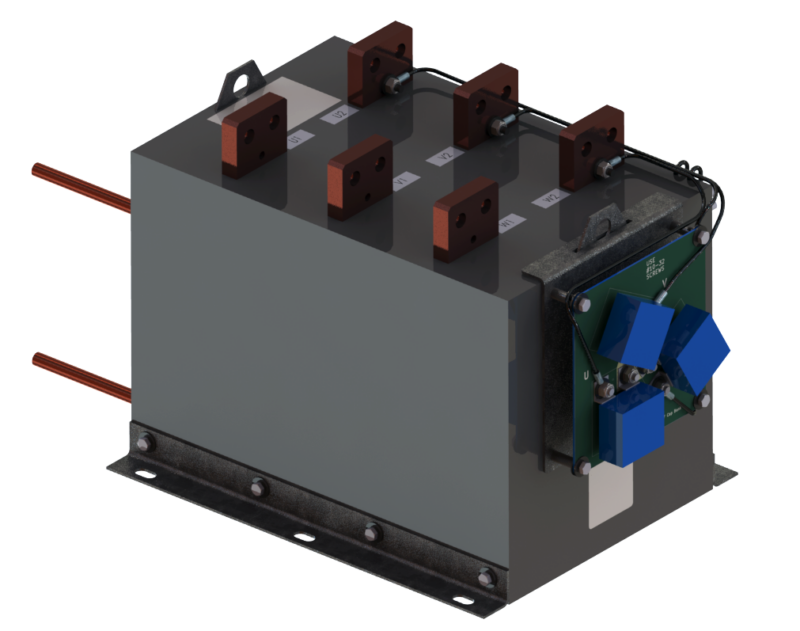

Motor Load Simulation Reactor

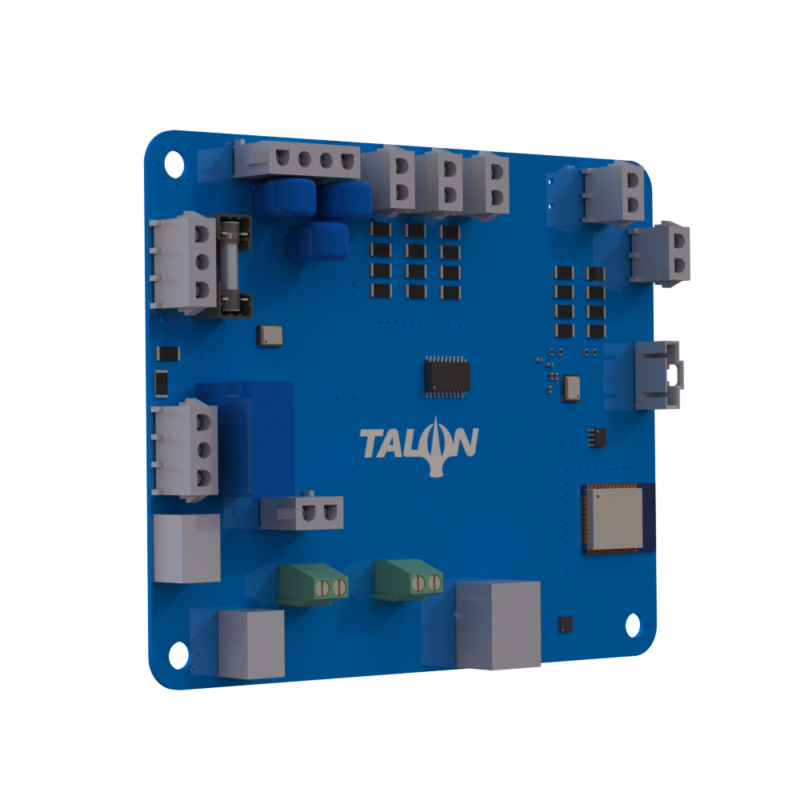

CTM Magnetics load reactor solutions are the future behind the electric motor revolution. From intensive research and development to robust production line testing and electric motor repair facilities, we are the driving force propelling the industry forward. With the capability to engineer high-frequency inductors up to 1,000 Hz, our solutions excel in testing inductive loads and motor controllers. What sets us apart is our innovative liquid-cooled technology, ensuring optimal performance. We proudly offer custom solutions tailored to meet the unique needs of our partners, with air-cooled options also available upon request.

Applications

CTM vs. The Competition

CTM

- High frequency capable (0-1,000Hz)

- Patented liquid cooled technology

- Highly efficient inductor technology

- Military grade shock & vibration

- Highest power density solution

The Competition

- Limited frequency capabilities

- Inefficient cooling system

- Inefficient silicon steel technology

- Low shock & vibration capabilities

- Lower power density

Product Highlights

Liquid Cooling

- Unparalleled power density

- Best in class thermal efficiency

- Minimal heat surrounding environment

- More flexible with packaging

Military Shock & Vibration

- Explosive and extreme shock & vibration tested

- Unparalleled ruggedness & longevity

High Power Density

- Smallest size & optimized cost

- Up to 60% reduction in volume compared to competitors

- Best in class performance

High Frequency

- 0 – 1,000 Hz capable

- No high frequency derate

- High efficiency at high frequencies

The Optimal Solution for Electric Motor Simulation

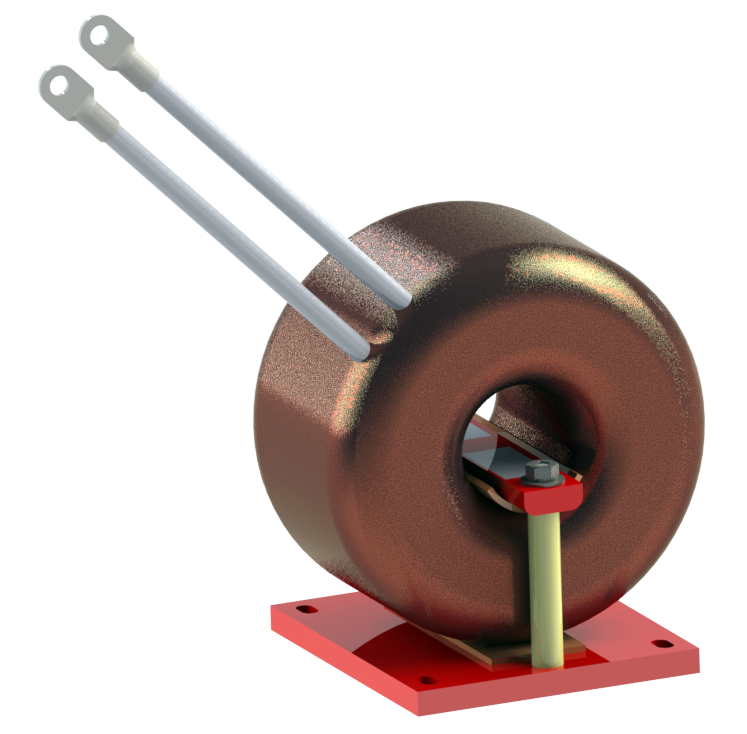

Inductor Efficiency:

CTM Magnetics patented toroidal technology enables highly efficient designs for high frequency applications.

High Frequency Capable:

Engineered to handle frequencies ranging from 0 to 1,000 Hz. This remarkable capability ensures precision and responsiveness in evaluating inductive loads, diverse current levels, and motor controllers, allowing your team to explore the full spectrum of electric motor performance with confidence.

Liquid Cooling:

CTM Magnetics patented liquid cooled technology enables higher thermal efficiency, power density, and performance. With liquid cooling, 97% of the transformer heat is captured by the coolant with only 3% released to ambient. By efficiently dissipating heat, our innovative liquid-cooled solutions not only enhance the performance and longevity of our electric motor simulation products but also provide a competitive advantage in pushing the boundaries of electric motor technology.

Power Density:

Innovative packaging and cooling systems, combined with highly efficient inductors enable unparalleled power density.

Military Grade Shock & Vibration:

CTM liquid cooled inductors have been tested and passed rigorous explosive and extreme shock & vibe military testing. CTM liquid cooled transformers are the optimal choice for electric motor testing applications.

Motor Load Simulation Reactor Specs

Voltage Range

Up to 690 V

Frequency Capability

0-1,000 Hz

Cooling Options

Liquid Cooled & Air Cooled by request

Enclosure Options

Modular Panel | NEMA 3R Cabinet | Custom Enclosures by request

Agency Recognitions

cRUus 1446 | UL 508 A

Overload Capability

200% rated current for 1 min (liquid cooled)

150% rated current for 1 min (air cooled)

Ambient Temperature Range

Maximum: 50 °C (122 °F) (air cooled) | 65 °C (149 °F) (liquid cooled)

Minimum: -40 °C (-40 °F) (air & liquid cooled)

Preventative measures should be taken to ensure the coolant does not freeze in the system.

Get a Custom Design in just 2 Business Days

We are here to work with you every step of the way.

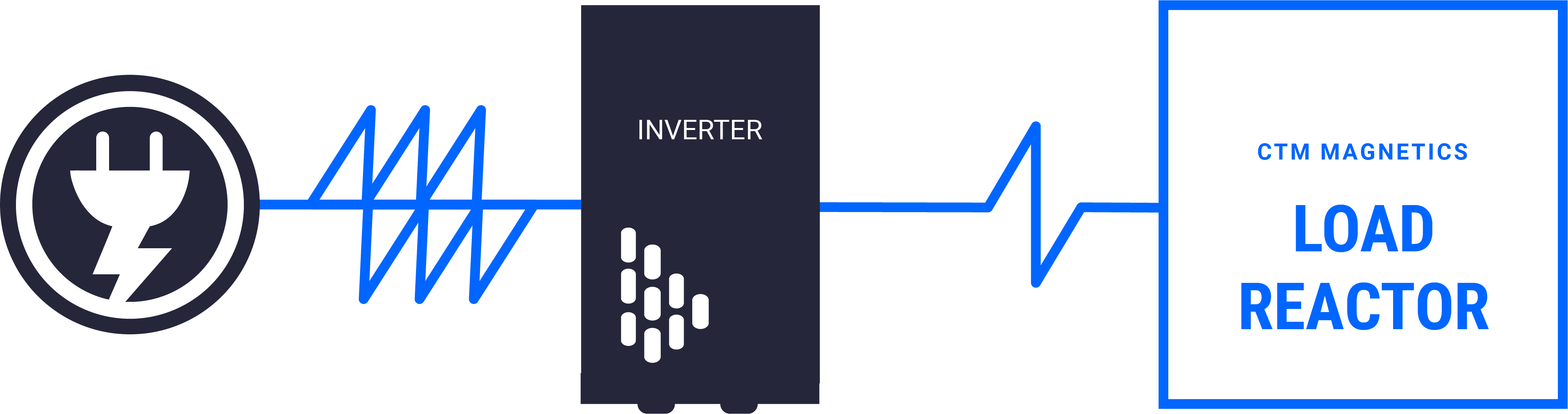

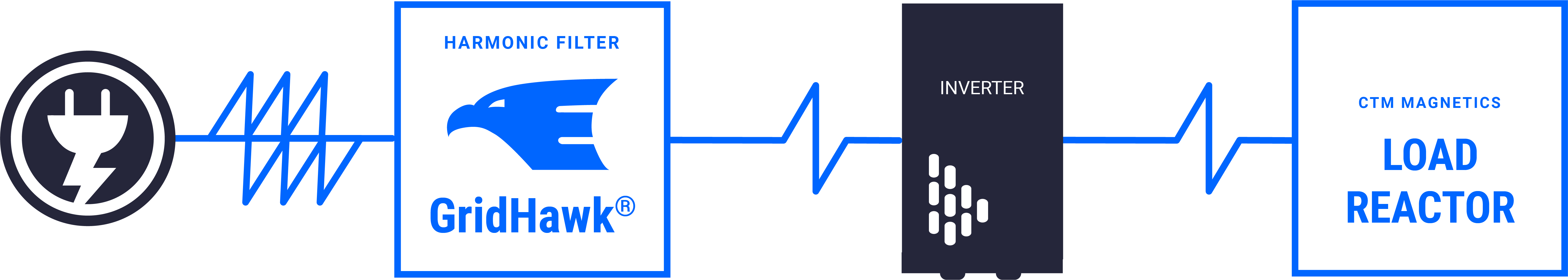

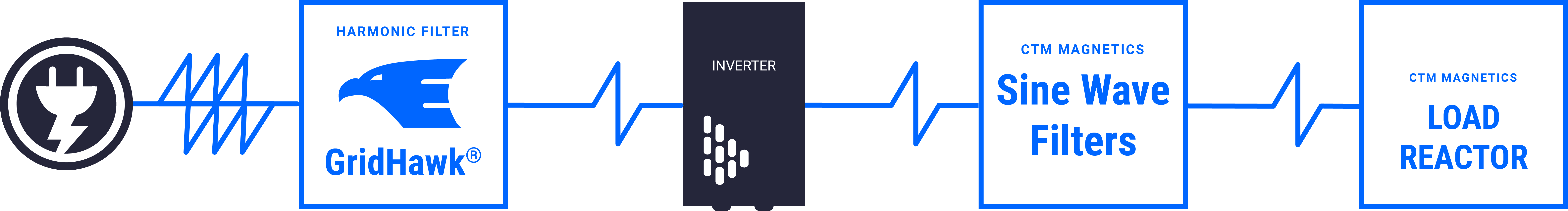

Other Other Products

Product Categories

-

Reactors

CTM input and output reactors mitigate harmonic distortion on the input and output of VFDs.

-

Harmonic Filters

GridHawk® harmonic filters are engineered to eliminate harmonic distortion and enhance power quality.

-

Sine Wave Filters

CTM output Sine Wave Filters eliminate switching harmonics produced by VFDs, protecting motors.

-

Transformers

CTM 3-phase transformers are the ideal choice when extreme shock & vibe capability or liquid cooling is required.