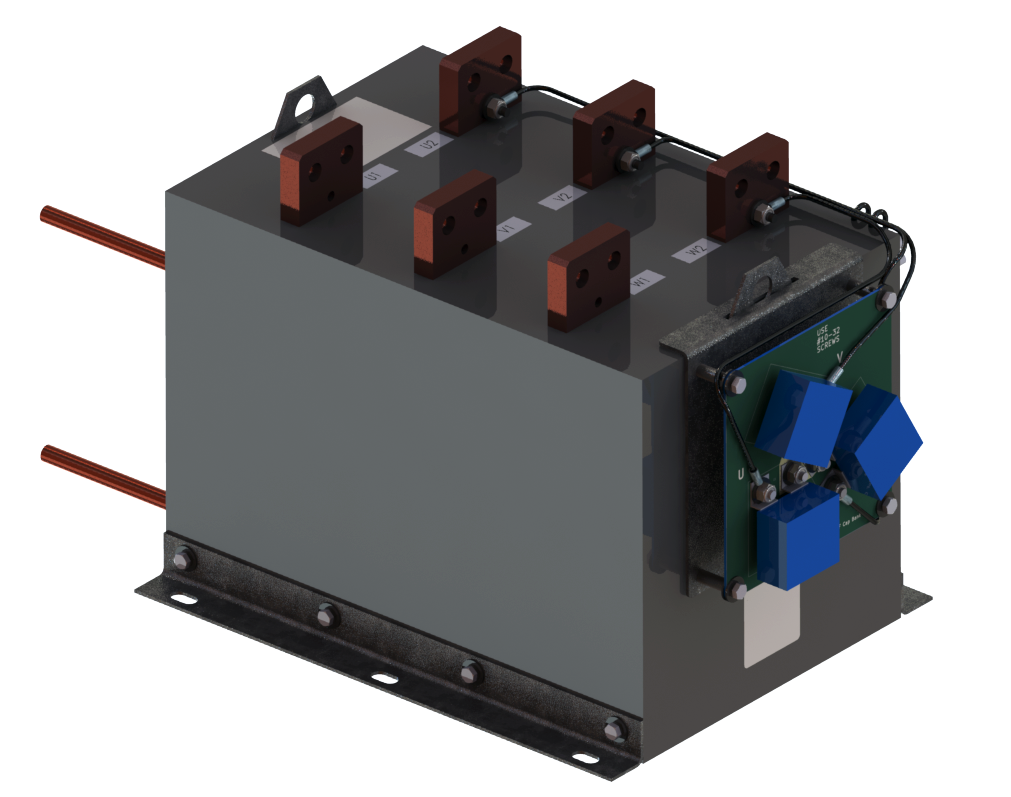

dv/dt Filters

Our dv/dt filters are designed to provide superior protection and performance for motor drives across various industries. By reducing drive output voltage dv/dt and voltage stress at motor windings, our filters protect AC motors from the destructive effects of peak voltages, increase motor service life, and improve system reliability.

Applications

dv/dt filters dominate in the most demanding applications, delivering unmatched performance and reliability for:

- Precision motor drives and inverters

- HVAC systems

- Mining and conveyor systems

- Electric vehicle powertrain testing

- Oil and gas operations

- Marine propulsion and onboard systems

- Machinery comprising servo or torque motors

Engineered to excel. Built to endure.

Reliable Power Protection

- Reducing Voltage Stress: Minimize destructive voltage spikes and protect motor windings from premature aging and failure.

- Lowering dv/dt Rates: Sharply reduce the rate of voltage change to safeguard motors and cables from insulation damage.

- Eliminating Overvoltages: Prevent harmful overvoltages caused by line reflections, ensuring stable motor operation.

- Enhancing Motor Lifespan: Extend the service life of AC motors by reducing stress on insulation and windings.

- Improving System Reliability: Deliver consistent performance and uptime for mission-critical applications.

- Reducing Electromagnetic Interference (EMI): Minimize noise propagation to neighboring equipment, ensuring cleaner operation.

Reliable Solutions Across Critical Industries

Industrial Automation and Manufacturing:

- Precision motor drives for CNC machinery, robotics, and automation

- Conveyor systems, material handling, and heavy equipment motor drives

- Pumps, compressors, and fans for industrial processes

Energy and Infrastructure:

- Motor drives for oil and gas pumping systems (e.g., ESPs and rod pumps)

- Inverters for solar, wind, and grid-tied energy storage systems

- Critical backup power systems and data center cooling solutions

EV and Marine:

- EV drivetrain systems, including hybrid vehicles and charging infrastructure

- Heavy equipment motor drives

- Shipboard power systems and electric propulsion drives

HVAC and Building Management:

- Energy-efficient HVAC motor drives for commercial and residential buildings

- Pumps, fans, and compressors for climate control solutions

- Precision motor drives for critical airflow systems

dv/dt Filters

Maximum Continuous Operating Voltage

3x690 VAC

Nominal Operating Voltage

3x550 VAC

Max. Peak Spike Voltage

2000 V

Rated Currents

12 to 1100 A @ 50°C

Overload Capability

1.5 x rated current for 1 minute, once per hour

Typical dv/dt Reduction

8 db - 12 db under full load conditions

Voltage Drop

<10 V @ 60 Hz

Inductor % Impedance

2.5% - 3.5% | 3% typical

Motor Frequency

0-120 Hz

Motor Cable Length

Up to 500 m

Switching Frequency

max. 16 kHz, depending on motor cable length & operating voltage

High Potential Test Voltage

P -> E 3300 VAC,1 minute

P -> P 3300 VAC (without caps), 1 minute

P -> P 2500 VDC caps, 2 s

Overvoltage Category

OV III (IEC 60664-1)

Temperature Range (operation & storage)

-25°C to +50°C fully operational

+40°C to +100°C with derating*

-25°C to +100°C transport and storage

Agency Recognitions

cЯUus 1446

Get a Custom Design in just 2 Business Days

We are here to work with you every step of the way.

Other Other Products

-

DC Link Chokes

-

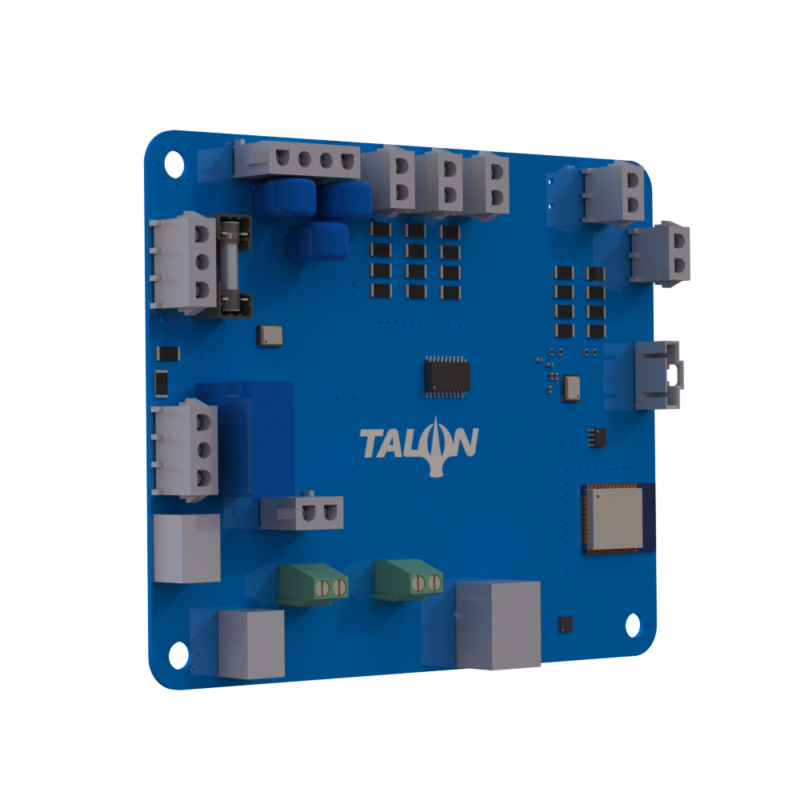

TALON™ Data Acquisition System

The optimal solution for comprehensive thermal protection and real-time data monitoring of energy systems.

-

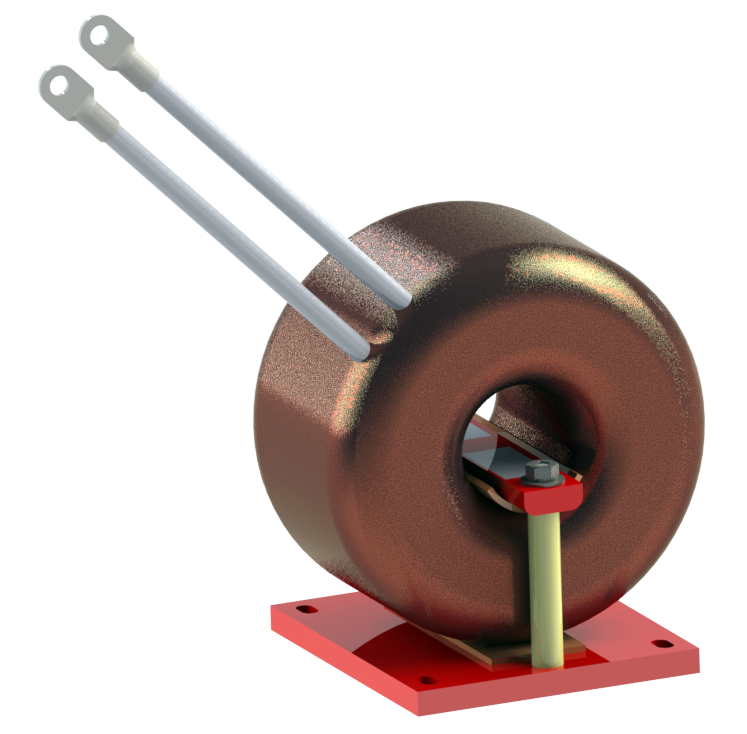

Motor Load Simulation Reactor

The ultimate choice for electric motor simulation, offering customized solutions designed specifically for testing inductive loads and motor controllers.

Product Categories

-

Reactors

CTM input and output reactors mitigate harmonic distortion on the input and output of VFDs.

-

Harmonic Filters

GridHawk® harmonic filters are engineered to eliminate harmonic distortion and enhance power quality.

-

Sine Wave Filters

CTM output Sine Wave Filters eliminate switching harmonics produced by VFDs, protecting motors.

-

Transformers

CTM 3-phase transformers are the ideal choice when extreme shock & vibe capability or liquid cooling is required.