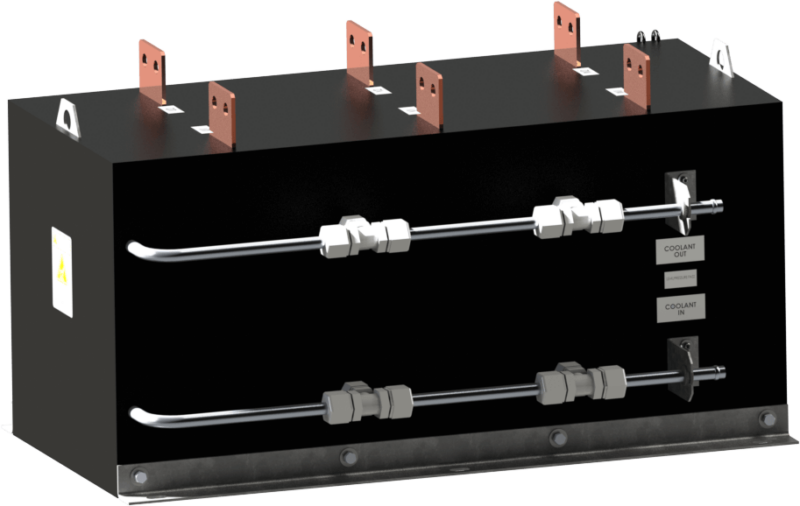

RLL Line Reactors

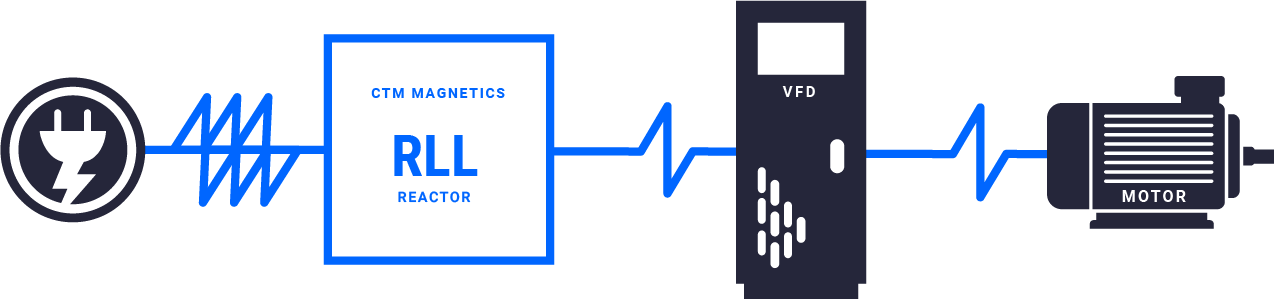

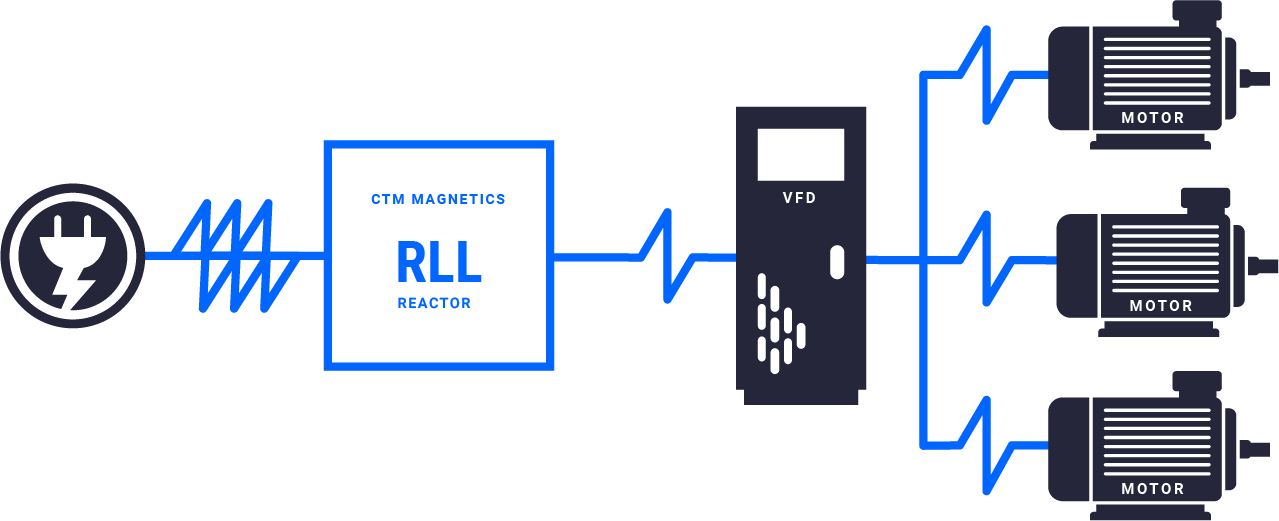

CTM Magnetics line reactors are designed for optimal performance with 60 Hz applications. Engineered for line side applications, these reactors are effective in mitigating harmonic distortion.

Applications

CTM vs. The Competition

CTM

- No common mode noise

- Highly efficient patented inductor technology

- Fully liquid cooled solutions

- Integrated cooling system

- Military grade shock & vibration

The Competition

- Produces common mode noise

- Inefficient silicon steel inductors

- Air cooled only

- Cooling system not included

- Low shock & vibration capabilities

Product Highlights

Efficient Design

- No derate

- Smallest size & optimized cost

Reliable Performance

- Thermally protected capacitors & inductors.

- Highly efficient patented inductors & capacitors.

- No common mode noise.

Plug & Play

- Simple 3-in/3-out connection

- No additional cooling required

Environmentally Rugged

- Dust, wind, rain, weather proof (NEMA 3R)

- Military grade shock & vibration capable

The Optimal Reactor Solution For Line Side Applications

Drive Protection:

CTM line reactors absorb voltage spikes, voltage transients, and other power line disturbances, extending the life of motor drive electronics, bridge capacitors, and semiconductors.

Minimize Nuisance Tripping:

AC voltage spikes lead to rapid rises in the DC Bus voltage, causing the inverter to shut-off due to over-voltage. Line reactors absorb voltage spikes, significantly reducing nuisance tripping.

Reduce Harmonic Distortion:

6-pulse rectifiers are nonlinear loads that create significant harmonics; line reactors provide impedance to reduce harmonics, helping applications meet IEEE 519.

Protect Sensitive Equipment:

Line reactors also provide protection for nearby equipment sensitive to harmonic distortion created by nonlinear loads.

Cost-Optimized Solution:

RLL Line Reactors are optimized for line-side filtering applications with bridge rectifications.

Inductor Efficiency:

CTM Magnetics patented inductor technology enables highly efficient reactor designs for both line and high frequency applications.

Power Density:

Innovative packaging and cooling systems, combined with highly efficient inductors enable unparalleled power density.

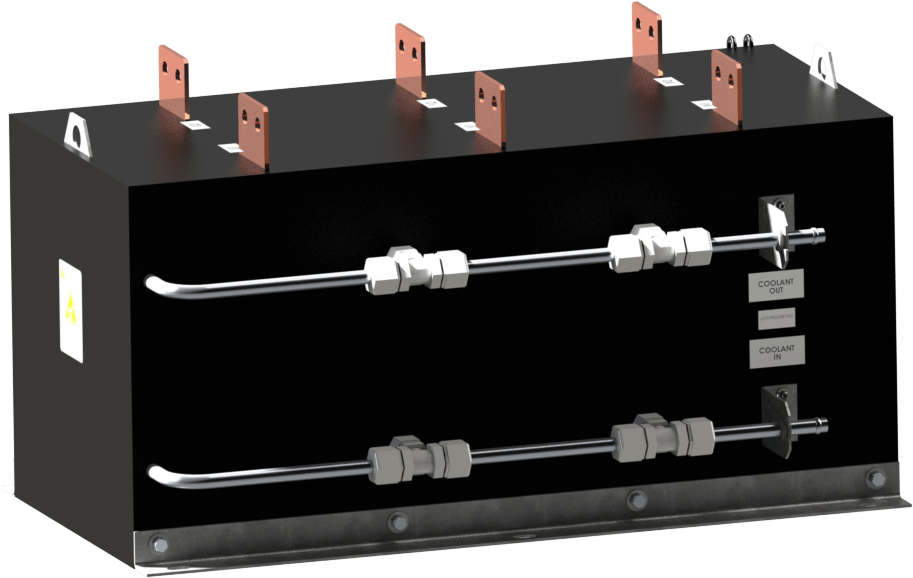

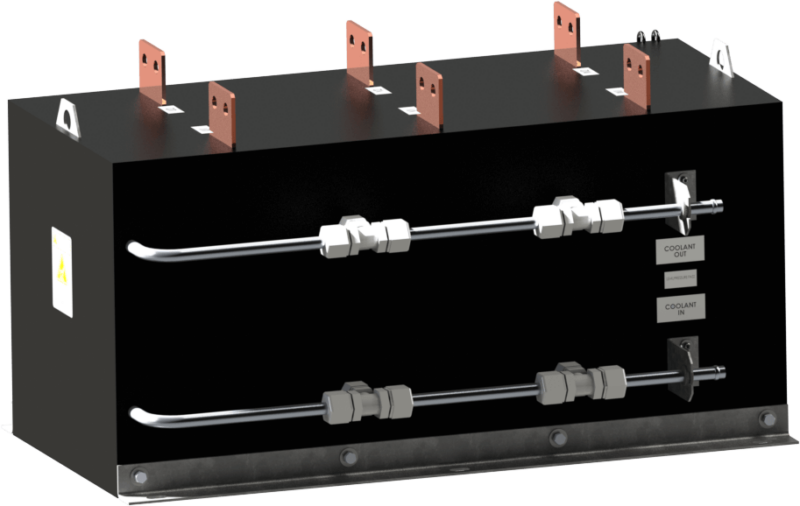

Liquid Cooling:

CTM Magnetics patented liquid cooled technology enables higher thermal efficiency, power density, and performance. With liquid cooling, 97% of the reactor heat is captured by the coolant with only 3% released to ambient. This reduces the need for additional cooling and allows for more flexibility in locating reactors near temperature sensitive equipment.

Military Grade Shock & Vibration:

CTM liquid cooled line reactors have been tested and passed rigorous explosive and extreme shock & vibe military testing. Liquid cooled line reactors are the optimal choice for mobile, marine, and military applications.

RLL Product Specs

Impedance Levels

3% and 5%

Voltage Range

Up to 690 V

Fundamental Frequency

50/60 Hz

Current Range

3% Z: 360 - 1,440 A

5% Z: 240 - 1,440 A

Overload Capability

150% rated current for 1 minute

Max Coolant Temp

50 °C (122 °F)

(higher with derating)

Plumbing Materials

Aluminum (standard)

Copper (option)

Heat Removal

97% to liquid coolant

3% to ambient air

Max Ambient Temperature

65 °C (149 °F)

Inductance Curve

81% at 150% load

68% at 200% load

53% at 300% load

Agency Recognitions

cЯUus 1446 | UL 508A

Get a Custom Design in just 2 Business Days

We are here to work with you every step of the way.

Other Reactors

-

RLF Line Reactors

The Optimal Reactor Solution For Line Side Applications

-

RPL Load Reactors

The optimal reactor solution for 60 Hz VFD applications.

-

RSL Reactors

The optimal reactor solution for high THID applications.

-

R4L Reactors (High Frequency)

The optimal reactor solution for high frequency VFD applications.

Product Categories

-

Harmonic Filters

GridHawk® harmonic filters are engineered to eliminate harmonic distortion and enhance power quality.

-

Sine Wave Filters

CTM output Sine Wave Filters eliminate switching harmonics produced by VFDs, protecting motors.

-

Transformers

CTM 3-phase transformers are the ideal choice when extreme shock & vibe capability or liquid cooling is required.

-

Other Products

We offer a range of power quality solutions designed to enhance efficiency and ensure robust, reliable performance. Our products help minimize harmonic distortion, improve energy efficiency, and promote smooth operations across demanding industrial and commercial applications. Whether optimizing motor drives, stabilizing power systems, or reducing electrical noise, our engineered solutions deliver the performance and durability needed for modern power infrastructure.