Reactors

Reactors are a common component used in motor drive applications. Positioned on either the input or output of the variable frequency drive (VFD), or on both sides, reactors help reduce harmonic distortion produced by the VFD. When additional harmonic filtering is required, the use of an input Passive harmonic filter (link) or an output Sine wave filter (link) may be required.

Variable Frequency Drives (VFD's)

Why VFD’s Are Important:

- VFD’s improve the efficiency of motor applications – resulting in energy savings

- VFD’s allow you to adjust the speed of electric motors to maintain constant torque load.

- They provide controlled starting and stopping of the motor.

How VFD’s Work:

- VFD’s convert line current from AC to DC, then back to AC

- VFD’s control the speed of a motor by varying the output frequency delivered to the motor

- VFD’s vary the output frequency by using IGBT’s that switch at higher frequencies.

Unintended Drawbacks of VFD’s For Line Side Applications:

- IGBTs create high frequency harmonics at the switching frequency of the drive.

- Harmonics can cause damage to motors requiring repair resulting in costly downtime.

- Drive output harmonics can be worse with higher fundamental frequencies and long cable lengths.

Unintended Drawbacks of VFD’s For Load Side Applications:

- Converting AC to DC or DC to AC creates harmonic distortion

- Harmonic distortion can negatively affect the power quality of utility grids and surrounding equipment connected to the same grid. Harmonics also can cause damage to motors requiring repair resulting in costly downtime.

- Utility providers are starting to enforce strict IEEE-519 guidelines for customers that utilize VFDs

Solving Harmonics with CTM Line & Load Reactors:

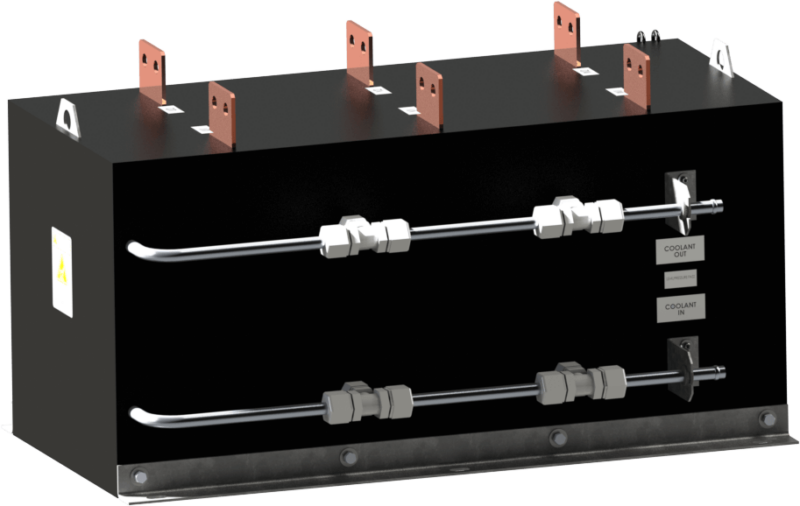

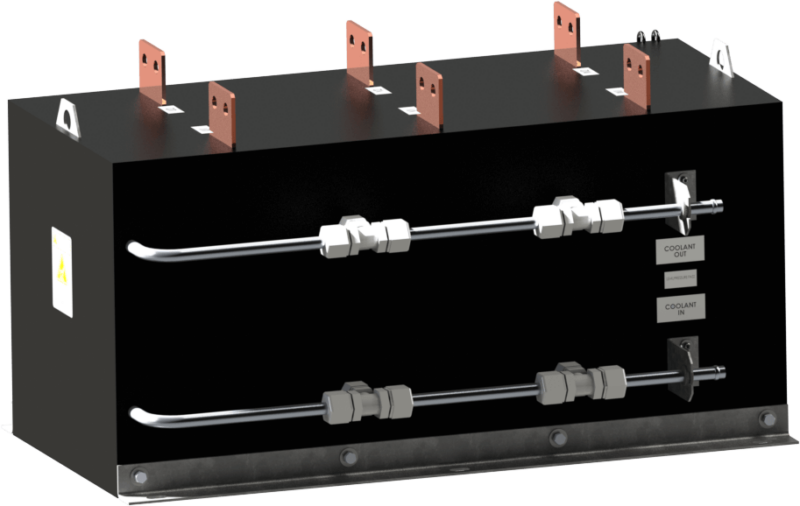

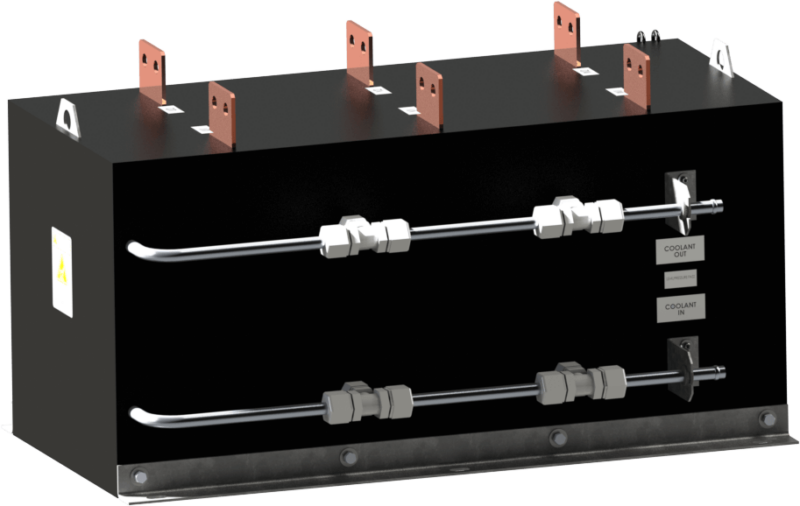

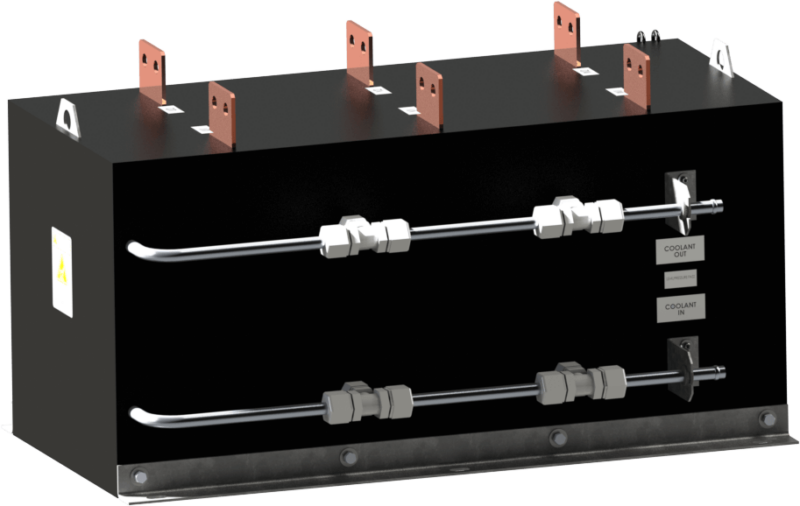

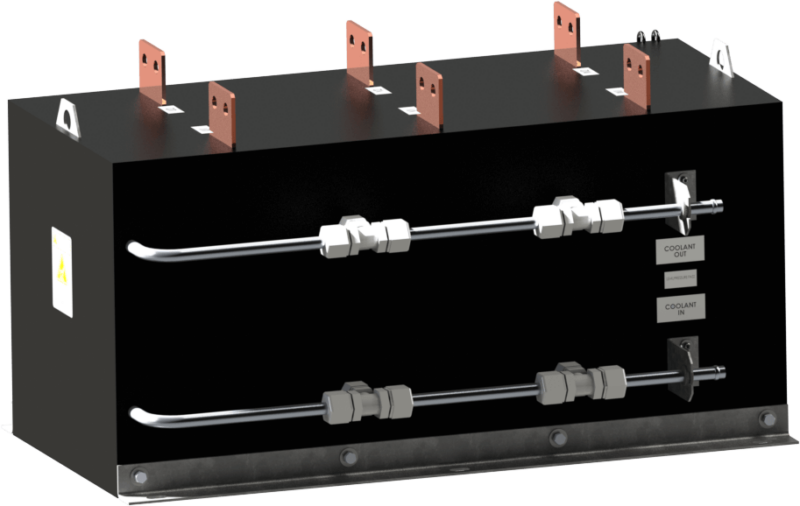

CTM’s Line & Load Reactors utilize patented inductor technology, along with state-of-the-art cooling systems to greatly reduce drive harmonics without adding significant heat to a drive cabinet.

CTM RLF Reactors are specifically designed for 60 Hz line and load applications. Leveraging our patented inductor technology, CTM RLF Reactors boast high efficiency, best in class power density, air or fully liquid cooled solutions, and multiple packaging options to fit your application needs.

As the market for higher speed, higher frequency permanent magnet motors continues to increase, the need for high frequency reactors has also grown. CTM RHF reactors are designed and optimized for high frequency applications. Most magnetic suppliers attempt to solve high frequency problems by oversizing traditional 60 Hz, silicon steel, reactors. This results in higher cost, increased size, and reduced efficiency. CTM Magnetics has been solving high frequency problems for decades by using high frequency proprietary materials. This leads to a size and cost optimized solution that maximizes efficiency.

Running a VFD with a CTM RLF or RHF Reactor Solves:

Harmonic Distortion

CTM reactors significantly reduce harmonic distortion, protecting motors and the grid.

High Frequency

With standard product lines ranging from 60 Hz – 500 Hz, CTM reactors are designed for demanding applications.

Lower CAPEX

CTM reactors offer best in class performance & reliability at low cost.

Products

-

RLF Line Reactors

The Optimal Reactor Solution For Line Side Applications

-

RLL Line Reactors

The Optimal Reactor Solution For Line Side Applications

-

RPL Load Reactors

The optimal reactor solution for 60 Hz VFD applications.

-

RSL Reactors

The optimal reactor solution for high THID applications.

-

R4L Reactors (High Frequency)

The optimal reactor solution for high frequency VFD applications.