High Frequency Filtering For High Speed Motors

High Frequency Motor Applications Require Extra Filtering

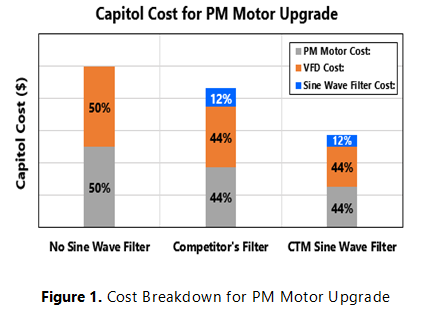

High frequency motor applications lead to higher harmonic distortion for the entire motor drive system. To account for this one can either reduce the harmonics by derating the VFD, increasing the drive cost and size, or derate the PM motor so that it can absorb the elevated harmonics while maintaining the desired HP rating. Either way, the CAPEX of the system will increase substantially, figure 1 below.

Conventional sine wave filters can take 15% THID from the VFD and filter it to 5% THID. The problem with adding a contemporary sine wave filter is that the cost of the filter is often greater than the cost to derate the PM motor.

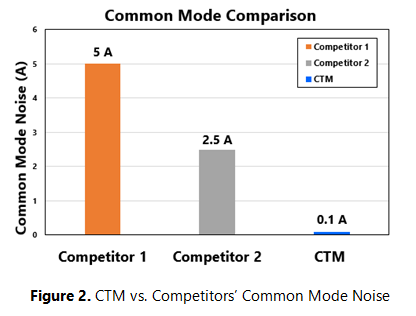

CTM sine wave filters are different. CTM FlexSine® and HighSine™ filters are able to reduce drive harmonics from 35% THID to 5% THID. The 35% to 5% relationship of the VFD/SWF/Motor will Lower CAPEX (investment) and OPEX. Furthermore, it will reduce the system’s overall size and weight without introducing additional common mode noise (figure 2 below). Optimize a motor drive system today by adding a CTM FlexSine® or HighSine™ filter.

" alt="">

" alt="">