Sealed Contactors Protect Outdoor Harmonic Filters

Sealed Contactors Protect Outdoor Harmonic Filters

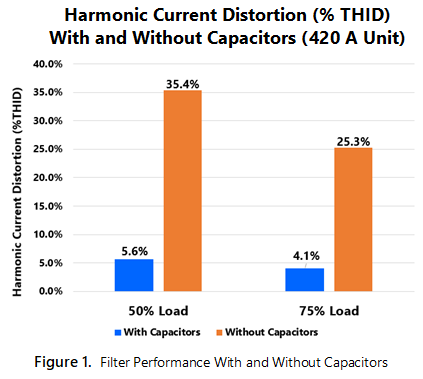

Many harmonic filters use NEMA 3R outdoor cabinets in blowing dust or high humidity environments. A harmonic filter awaiting installation in the field for 30 days can collect enough dust on the contactor to fail on startup. Furthermore, a failed contactor removes the capacitors from the harmonic filter circuit, severely reducing filter performance, see figure 1 below. However, sealed contactors protect outdoor harmonic filters from this contamination.

Unfortunately, it is difficult to detect failed contactors in a unit without continuous grid monitoring. As a result 35% THID is sent to the grid instead of 5% THID. Therefore, how much of the large voltage distortion problems in the Permian Basin result from harmonic filters with failed contactors? In short, measure your harmonic filter performance, you paid for capacitance and 5% distortion, not 35% distortion.

Sealing contactors requires electrical, mechanical, thermal, and compliance engineering knowledge and testing. For this purpose, CTM reviewed and tested many options prior to selecting a sealed contactor solution. Additionally, CTM manufactures harmonic filters in our UL 508A listed panel facility. Our sealed contactor solution maintains our UL listing. Sealed CTM contactors have been thermally and environmentally tested to ensure full ratings and a long life expectancy. 100% of CTM’s GridHawk®, GridHawk® HD, and GridHawk® XD harmonic filters now have sealed contactors suitable for outdoor harsh environments.

Contact CTM today for more information.

Download White Paper

" alt="">

" alt="">