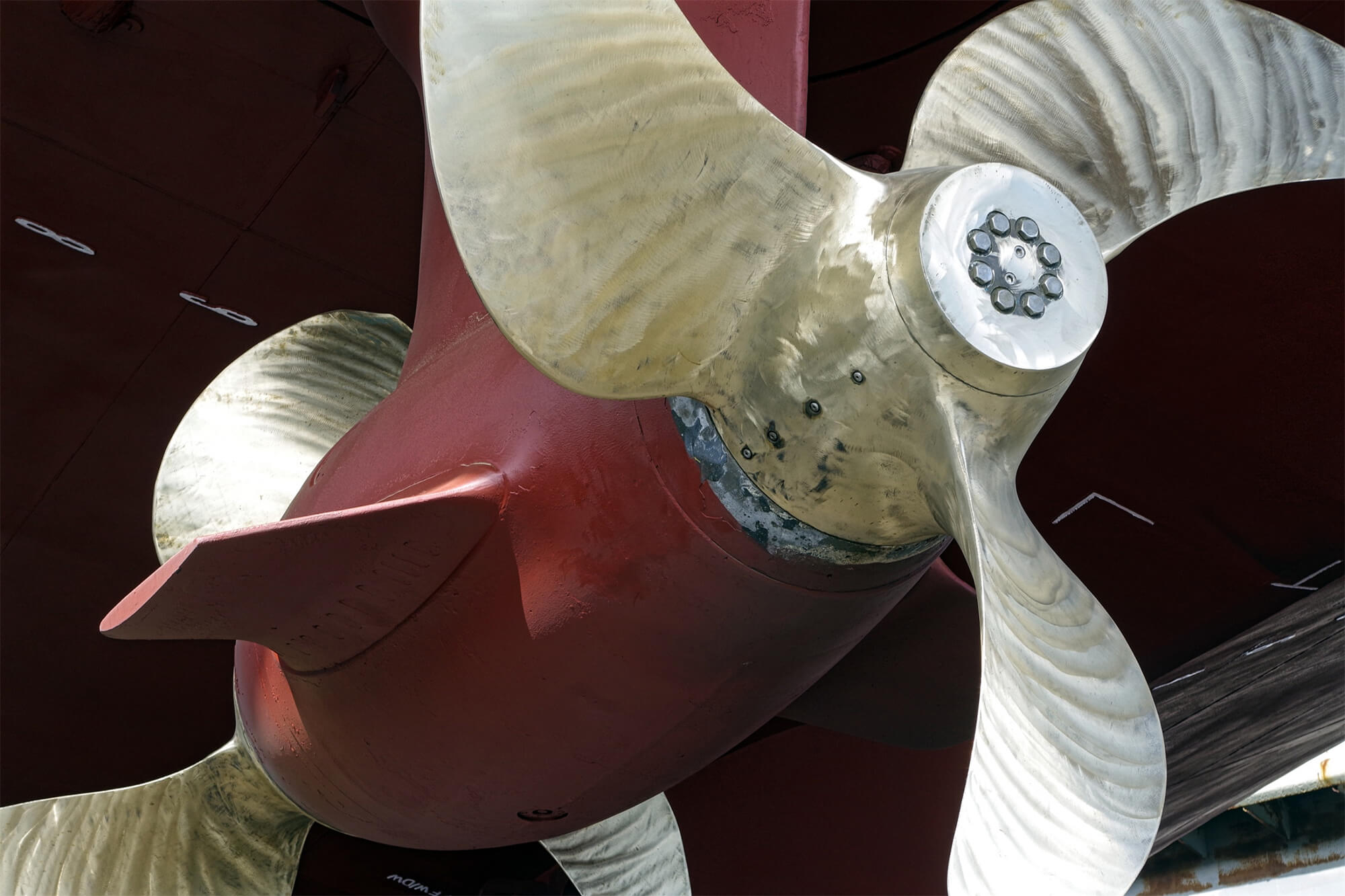

Compact Efficiency: CTM products are Ideal for the needs of Marine applications

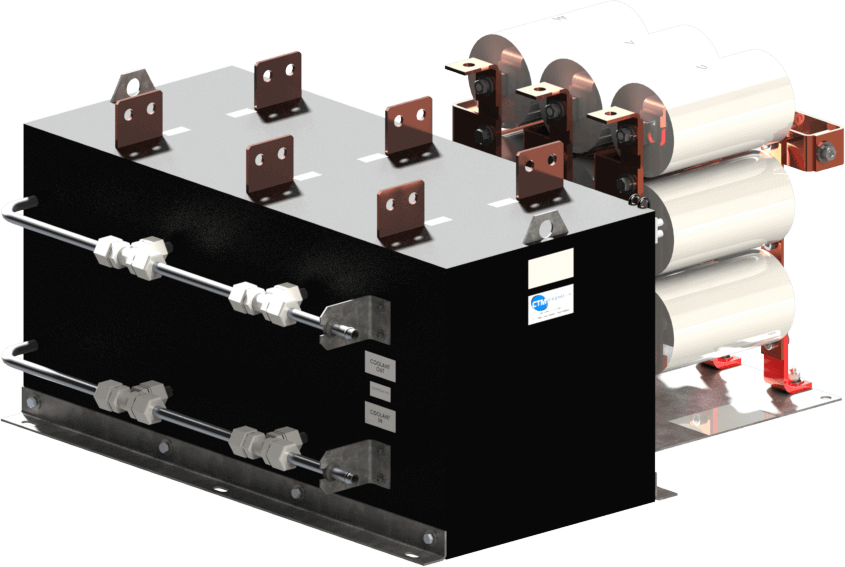

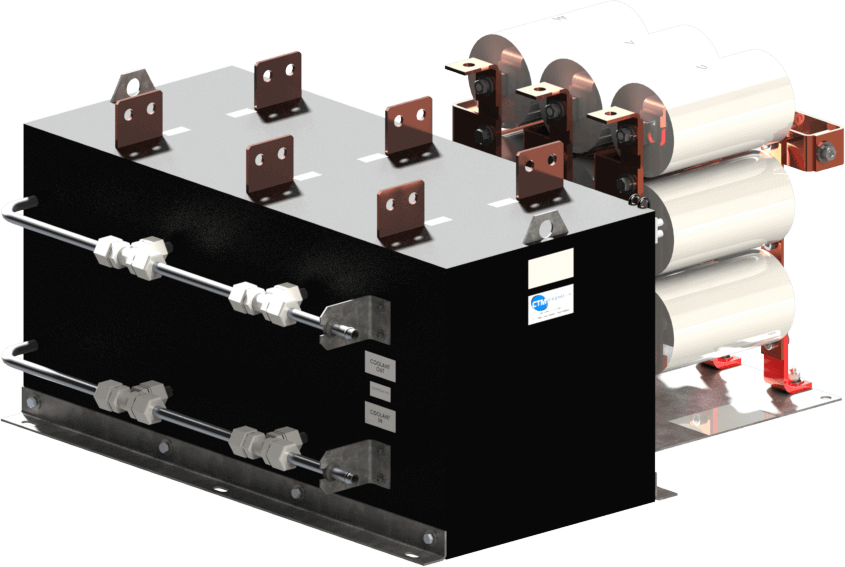

CTM Magnetics air & liquid cooled solutions are changing the way engineers design marine power systems. In marine applications, size and efficiency are critical. CTM Magnetics liquid cooled solutions boast best in class power density (up to 60% reduced volume and weight vs competitors), thermal efficiency, and extreme duty shock & vibration capabilities. A common marine power design practice involves locating major heat producing electrical components, such as magnetics, in a central location where they can be cooled. Traditional magnetics often need to be located away from heat sensitive equipment, adding limitations to equipment location resulting in longer power runs and higher system cost. With 97% of generated heat captured by the coolant, CTM Magnetics patented liquid cooled technology provides designers more flexibility in locating magnetics and optimizing valuable onboard space.

How we help the Marine industry

Power Density

CTM proprietary inductor technology coupled with state-of-the-art cooling systems result in the highest power density solution on the market.

Fully Liquid Cooled Solutions

CTM Magnetics patented liquid cooled technology enables 97% of generated heat to be captured and removed by the coolant. This creates more flexibility in locating magnetics and optimizing valuable onboard space.

Shock & Vibration Capabilities

CTM products have been tested and passed rigorous explosive and extreme shock & vibe military requirements.

Products that are the perfect fit for the marine industry

-

Sine Wave Filters

Sine Wave Filters

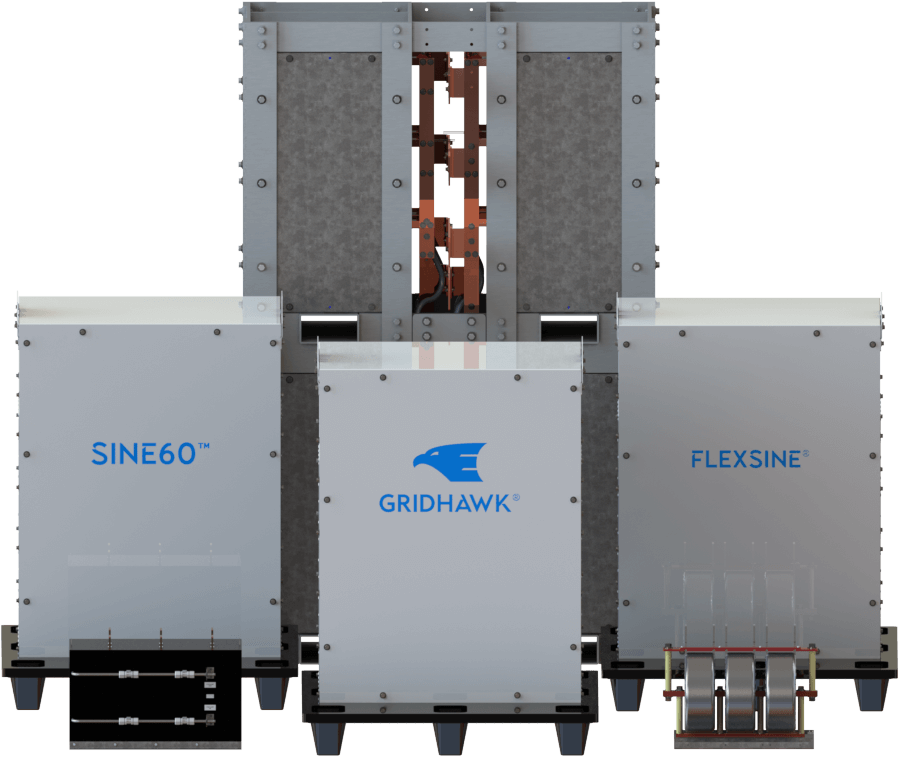

Sine 60™ (60 Hz)

The optimal solution for 60 Hz motor protection.

-

Sine Wave Filters

Sine Wave Filters

Flexsine® (60 - 120 Hz)

The optimal solution for 120 Hz PM motor protection.

-

Harmonic Filters

Harmonic Filters

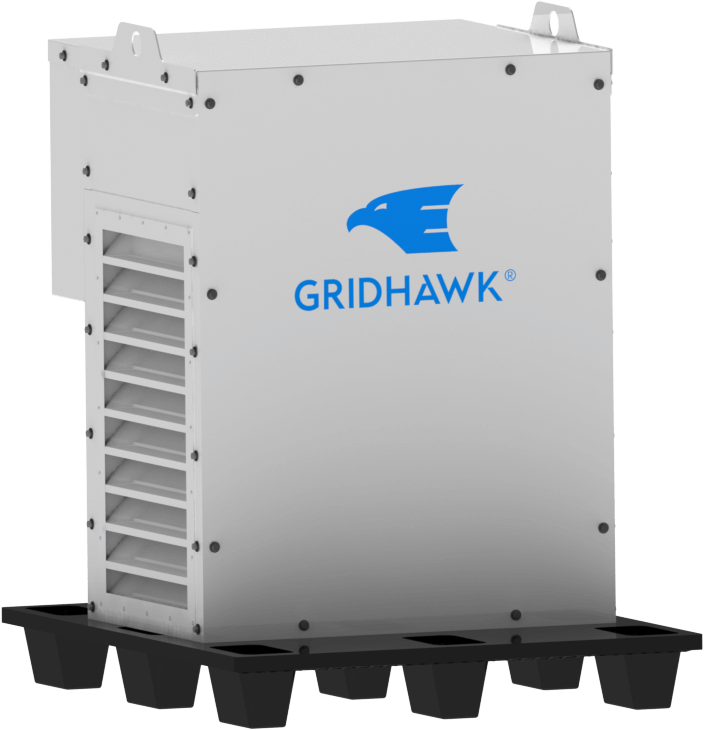

GridHawk® Passive Harmonic Filters (60 Hz)

The optimal solution for 60 Hz grid protection and IEEE-519 compliance.

-

Transformers

Transformers

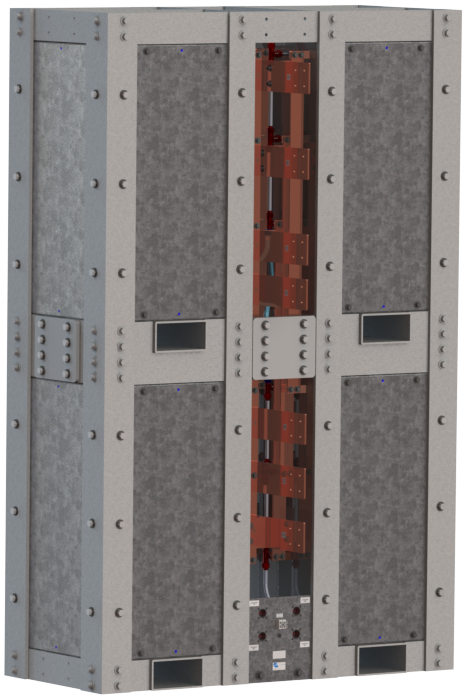

3-Phase Transformers

The optimal 3-phase transformer solution for high shock & vibe, high frequency, or liquid cooled applications.

We are here to work with you every step of the way.