Efficiency Refined: CTM Sine 60 & FlexSine Lead the Way for High Frequency Motor Applications

CTM Magnetics air & liquid cooled solutions enable our Oil & Gas partners to achieve higher speeds down hole for ESP applications. CTM GridHawk® harmonic filters are a revolutionary approach to meeting stringent IEEE-519 requirements, even in highly distorted grid environments, such as the Permian. Through the use of CTM’s patented filter technology, our solutions offer unparalleled benefits, including reliability, performance, size, and cost.

How we help the Oil & Gas industry

No Distortion Derate

All CTM GridHawk® harmonic filters are rated to handle ≤ 15% grid voltage distortion without requiring a costly derate. Most manufacturers derate their filters above 5% grid voltage distortion preventing IEEE-519 compliance while adding significant cost and size.

Reliability

All CTM Magnetics filters utilize highly reliable film capacitors that offer numerous benefits over electrolytic capacitors. Capacitor contactor failure is a leading cause of poor filter performance. All CTM contactors used in GridHawk® harmonic filters are protected by an environmentally sealed container, ensuring reliable performance in even the most extreme environmental conditions. Paired together with a robust thermal protection circuit, CTM GridHawk® harmonic filters guarantee reliable performance year round.

High Frequency

CTM proprietary inductor technology enables the use of higher frequency/speed induction and permanent magnet motors. The use of highly efficient materials allows for greater frequency capability without requiring a costly derate.

Products that are the perfect fit for the Oil & Gas industry

-

Harmonic Filters

Harmonic Filters

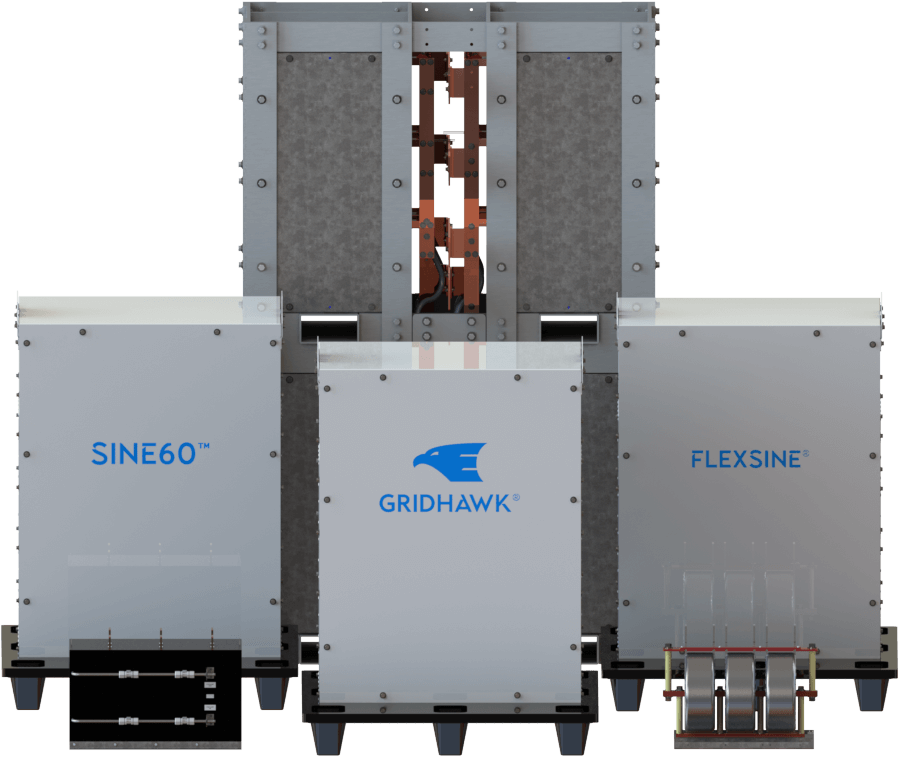

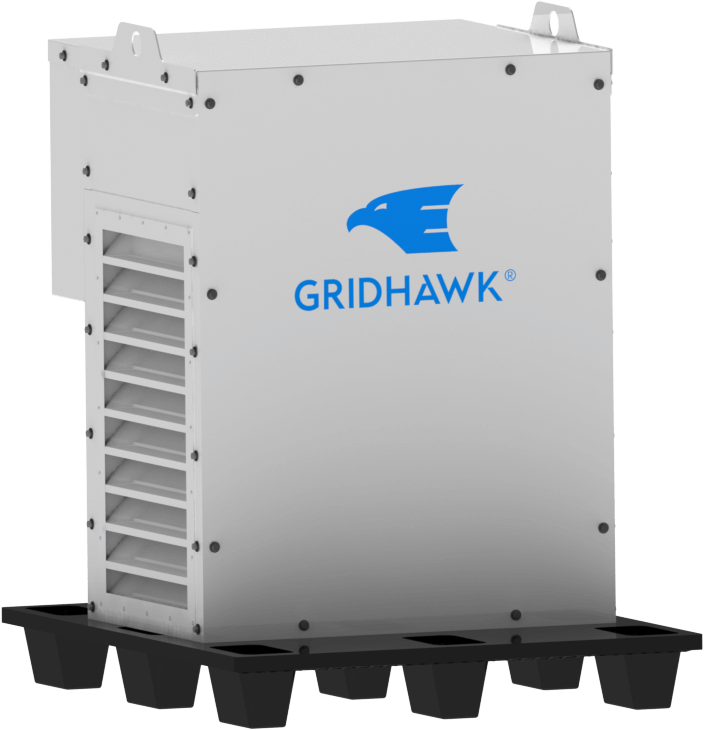

GridHawk® Passive Harmonic Filters (60 Hz)

The optimal solution for 60 Hz grid protection and IEEE-519 compliance.

-

Sine Wave Filters

Sine Wave Filters

Sine 60™ (60 Hz)

The optimal solution for 60 Hz motor protection.

-

Sine Wave Filters

Sine Wave Filters

Flexsine® (60 - 120 Hz)

The optimal solution for 120 Hz PM motor protection.

We are here to work with you every step of the way.