Maximize Energy Efficiency & Reduce Costs with CTM Magnetics

Problem: Energy Pollution

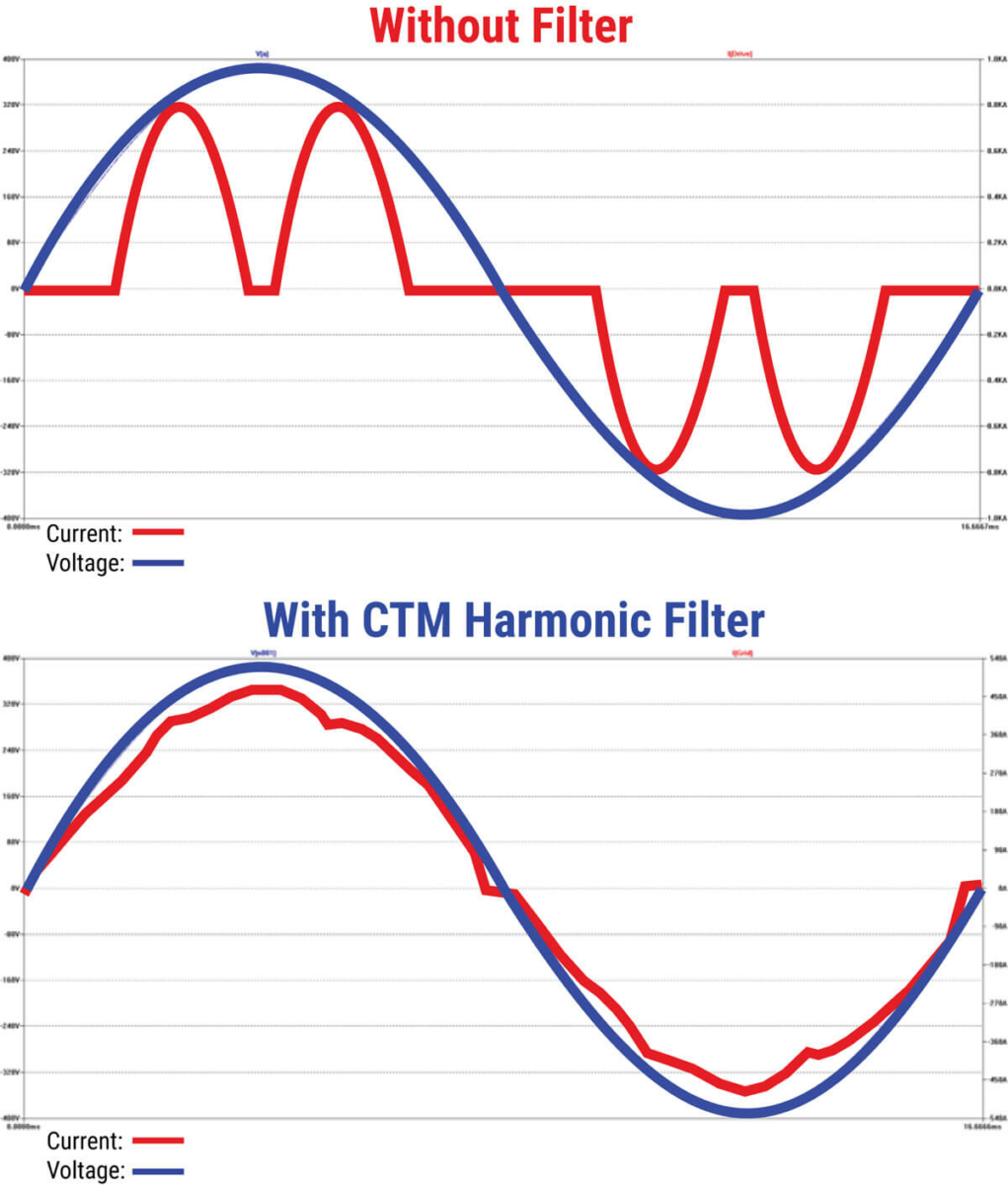

The ongoing technological development and restructuring of the grid bring about an increased number of sophisticated electrical equipment being installed at all levels of the power system. Such a massive proliferation of power electronics in the power systems raises the problem of harmonic pollution. This pollution can cause a range of issues, including premature equipment failure, decreased energy efficiency, and higher operating costs. In order to combat these problems and address the energy crisis, it is important to use products that can effectively remove energy pollution and improve power quality.

What We Do

CTM Magnetics is a leading manufacturer of power quality equipment. Our products include Harmonic Filters, Sine Wave Filters, Transformers, and Reactors for both line-side & load-side variable frequency drive (VFD) applications. Our products effectively remove energy pollution and improve power quality leading to better system reliability and greater energy efficiency. CTM Products are used in a variety of industries, including Oil/Gas, Marine, Agriculture, Battery Storage, EV/Charging, the US Military, and many other industries with demanding power needs.

What Set Us Apart

-

High Frequency Applications (60Hz - 2,000Hz) — Learn More

-

Forced Air-Cooled & Direct Liquid-Cooled Solutions — Learn More

-

Application Specific Packaging Expertise — Learn More

Improve Power Quality & Increase Profitability

High harmonic distortion (energy pollution) forces equipment to run hotter and less efficient, increasing the risk of premature failure. The outdated market solution to this problem has been to derate (oversize) power equipment. The problem with this approach is that it results in a larger than needed system that costs more and is less efficient. CTM Magnetics is disrupting this market belief by providing innovative products that improve power quality thereby eliminating the need to derate power systems. The result is a smaller, highly efficient, and extremely robust solution leading to maximized CAPEX & OPEX savings.

Increase System Reliability

Improving the power quality of a system increases its reliability. Harmonic distortion can cause equipment to malfunction or fail, leading to costly downtime and disruptions. By eliminating energy pollution, CTM Magnetics products help to reduce the risk of equipment failure while improving system performance, resulting in increased longevity.

Solution: CTM Magnetics

With energy pollution on the rise, it is important to identify solutions that address the energy crisis. CTM Magnetics products help create more energy efficient systems, improve system reliability, and lower capital & operating costs. These products are important tools in the fight against poor energy quality and should be considered by any company looking to reduce energy usage and optimize system cost.

" alt="">

" alt="">